In order to get optimum capacity and maximum wear life of wear parts and crusher parts, consider the following points:

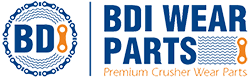

Check the feed size and gradation:

• Oversize feed material decreases capacity and can cause abnormal wear of the liners

• Too small a feed size for the cavity increases the wear at the bottom part of the liners and may cause poor utilization of the wear parts

Check the feed arrangement:

Evenly distributed feed will result in more steady power and crushing force.

Check the power draw. Crusher should operate with a steady power draw and as close to full rated power as practical, depending the circuit design and the ability to control system.

Check the closed side setting. The setting should be close to the required product. The setting is too small if the adjustment ring is moving on the main frame (ring bounce).

Check the crusher operating speed

Check the cavity in use

• Based on feed size

• Based on required end product size which determines the required setting range

• Check the crushing reduction ratio

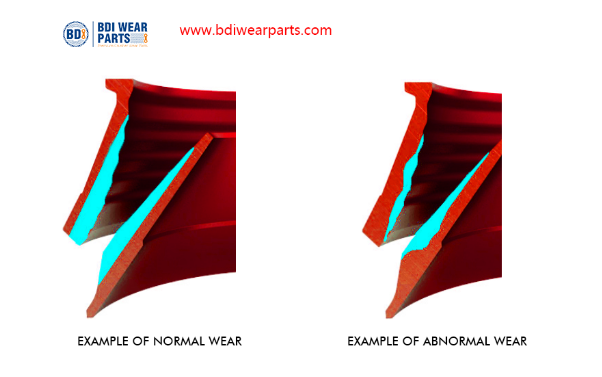

Check the wear profile of the liners: a distorted wear profile may decrease capacity, increase the liner wear rate and increase the crushing force.