Production Tour

BDI Wear Parts have always been trying to produce "proper" manganese steel castings; quality control and process management play very important parts of our day to day operations. Let’s take a tour on how we make our products:

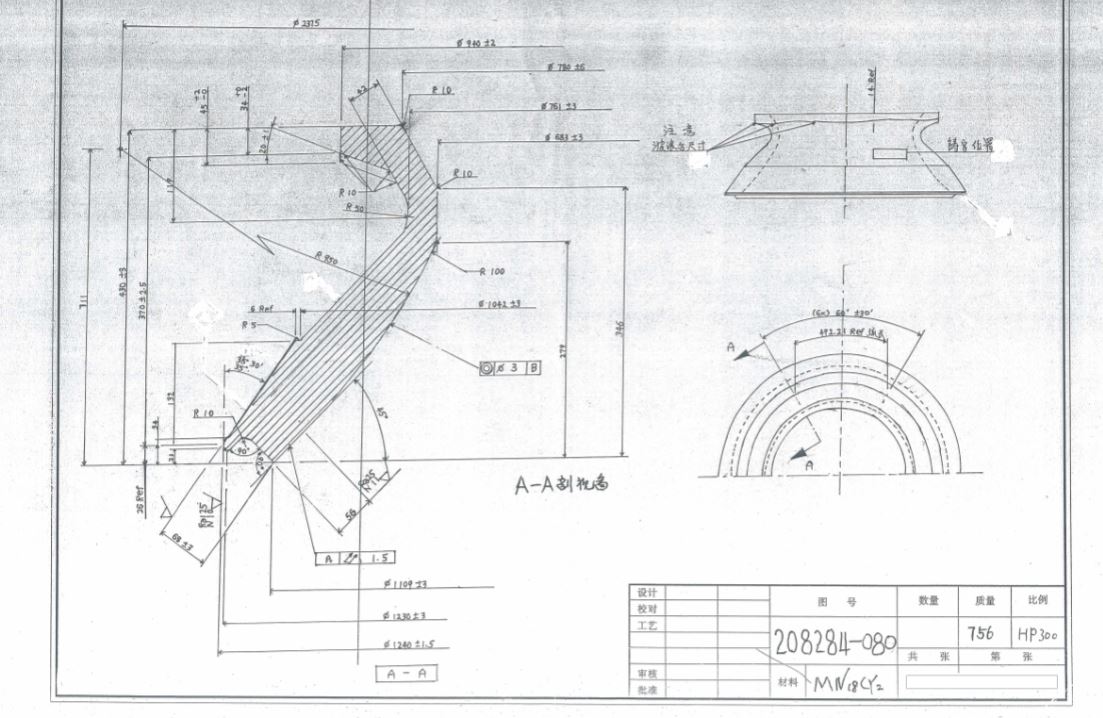

No.1 When a new product is introduced, our design team “translates” the drawings

supplied into product sheets:

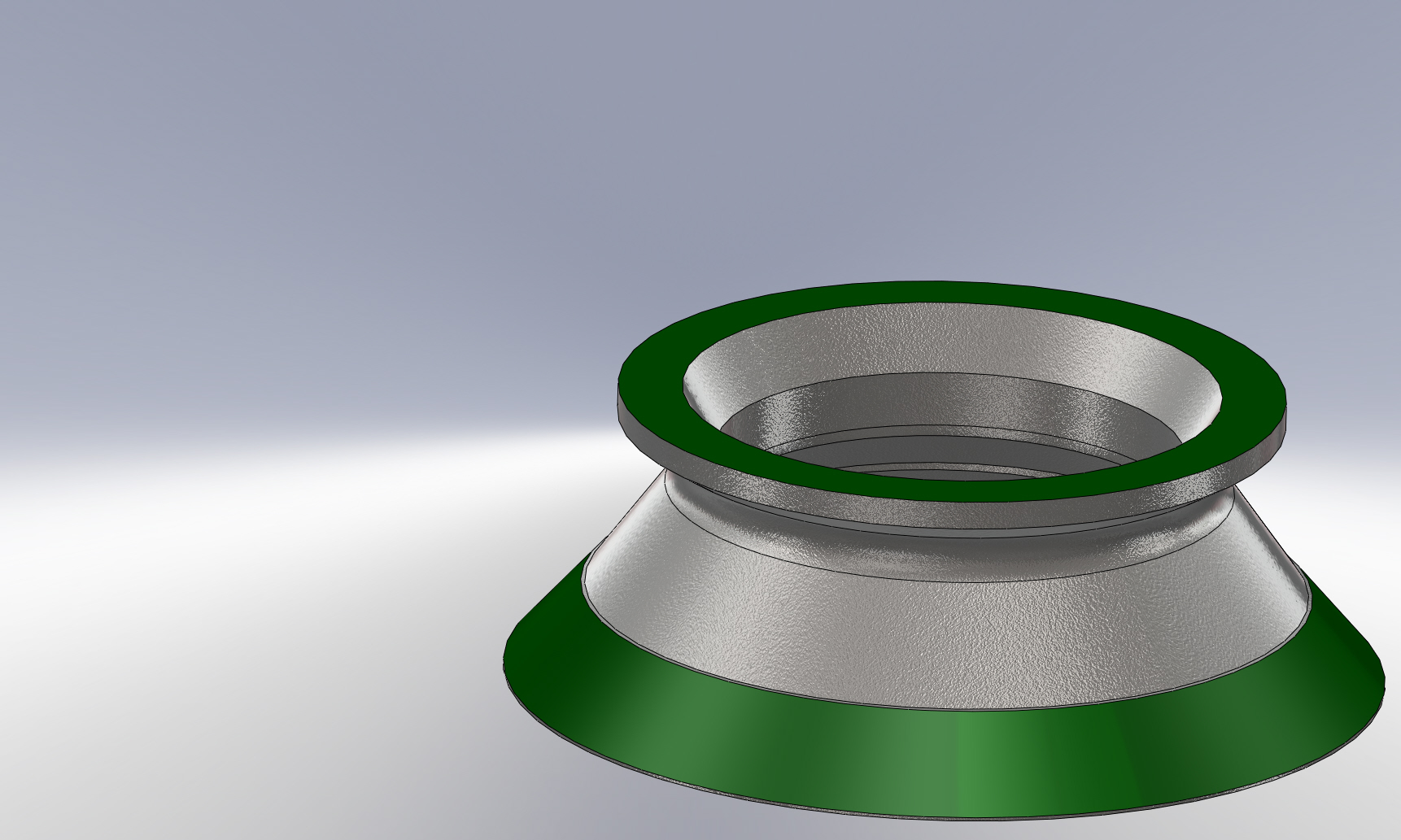

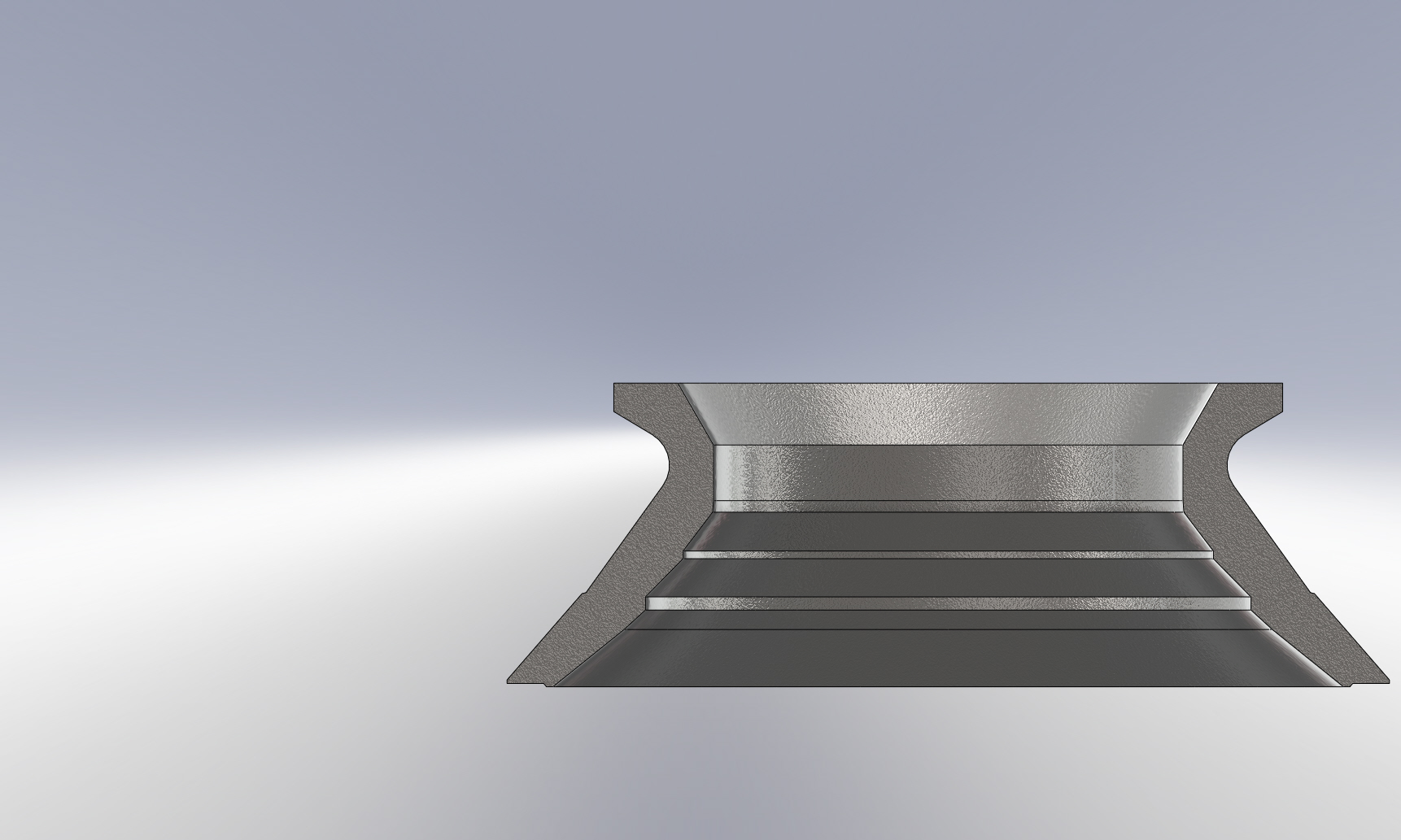

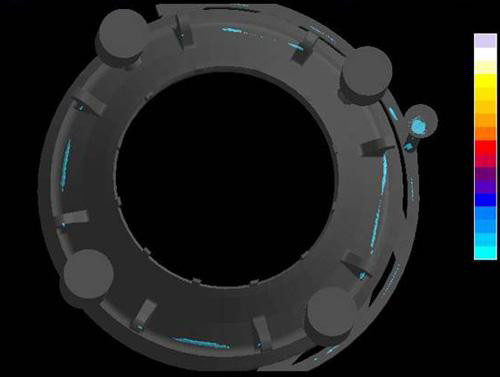

No.2 A 3D model of the product is created for better understanding and will be used for simulations

No. 3 Technicians then performs simulations to determine best quality control and pouring method

No. 4 Patterns are made for each product (BDI use STEEL patterns)

No. 5 The pouring area

No. 6 Product Pouring (we use bottom pour ladles)

No. 7 After 72 hours of cooling time, gating and risers (feeders) are ready to be removed.

No. 8 We use computer controlled heat treatment furnaces for all of our products.

No. 9 We use running water for quenching

No. 10 Products are treated and getting ready to be machined

No. 11 Products are carefully tooled so they can be installed properly.

No.12 Products are then going through final clean up and QA

No.13 Liners are painted as per customer’s requests.

No.14 Products being shipped to our customers all around the globe.